top of page

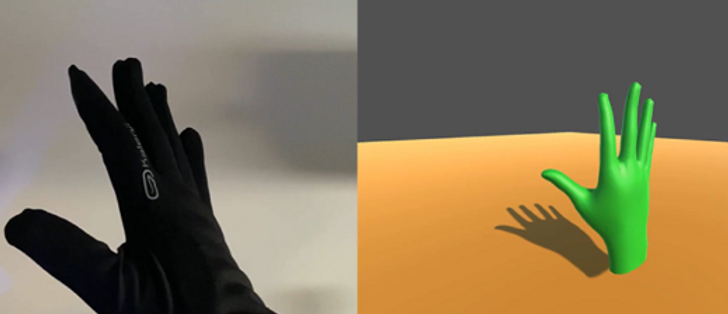

In this ongoing project custom made soft resistive sensor is being developed with the aid of conductive carbon ink in the microchannels. The sensor is designed as wearable and to conform to finger motion. In addition to hardware development, the Unity interface will be developed and tested as well as characterization of the conductive ink traces.

Here is an open-source and low-cost peristaltic pump project for soft robotic, micro-fluidic applications and bio-applications. For this project 4 3D print part is required, no support with PLA, tolerances are already arranged in design files. Arduino script is based on continuous rotation and can be modified for different speeds/directions.

bottom of page